2000 lb Butter Churner

In light of all the knowledge generated by this R & D work on the development and improvement of butter churns, today, IAI is able to offer equipment with a much higher level of reliability and performance. Briefly, our butter churns now enjoy the following features: • Better choice of materials (stainless steel, brass, etc.) to minimize wear and thus increase service life; • Increased reliability of mechanical components, as well as availability of spare parts; • Stronger structure, especially that of the frame. IAI also offers its clients a repair and maintenance service for butter churns in operation. Now, with our new mechanical base, customers can install their existing 1,200-lb, 1,600-lb or 2,000-lb tanks and certain spare parts, such as the engine and gears, can still be used on our base.

5000 lb Butter Churner

Our butter churners are equipped with internal baffles and are available in various sizes and a range of capacities. They have been designed through finite element structural calculations. Our calculation method has allowed us to reduce to the mechanical stress points to a minimum, making it a robust and durable high performance churner. This unit has a capacity of 5000 lb.

Opti-Fine

Our OPTI-FINE unit is designed for solid/liquid separation. It has been developed entirely by IAI. It allows for the recovery of nearly all particles that remain in the cheese after the production process. The reinjection of the recovered micro-particles at the end of the process results in a substantial monetary gain for the manufacturer. The achieved process rate can be as much as 75 000 litres per hour.

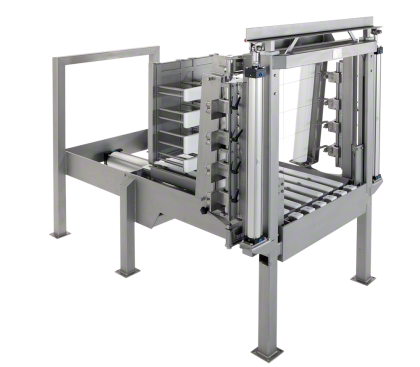

Automated Packer

This versatile piece of packing equipment includes programmable automation and an indexing system that allows for the treatment of different groups of products according to their required boxing formats.

Fully Automated Unstacker

This fully automated unstacker was entirely designed by IAI's control and engineering department. The unit is able to detect the presence of three different types of support racks and to complete depalletizing operations automatically.

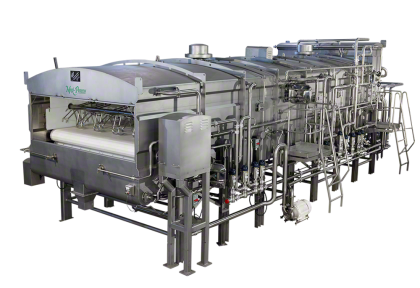

Second-Generation Maxi-Process Cheese Belt with a 7,000 kg / Hour Production Capacity

This second-generation Maxi-Process unit has a production capacity of 7,000 kg / hour of fresh cheese, equivalent to 14,000 blocks of cheese of 500g per hour. Maxi-Process is used in industrial cheese production and the various equipment incorporated in it make it possible to carry out treatments during cheese production. It should be noted that the Maxi-Process is fully-developed and manufactured by the multidisciplinary IAI team.

35 000 litres Storage Tank

Storage tank of 35 000 L with atmospheric pressure, including a 11ga vertical wall made in 304 stainless steel. The unit's dimensions are of 154'' x 114''; Manhole 16'' x 20''. Includes QMI sampling valve, removable washing balls, large surface agitator with low impact, 5 hp Eurodrive motor, and dimpled membrane with a 35 Ra finish.

Pressing, Draining and Cutting Table for Swiss Cheese

This pre-pressing table for Swiss – as well as other types of cheese – is considered to be a basic piece of equipment for pre-pressing and draining curds. It is semi-mechanized to facilitate its operation and increase rates of production. This table is built entirely with high quality steel. Because of its interior surfaces of 32ra finish and its high manufacturing, it meets 3A standards. An optional curd agitation system is also available. The conveyor and cutter are mechanized and all pressing functions are controlled by an Allan Bradley Programmable Logic Controller. Moreover, it is equipped with a HMI touch screen as well as a CSA-approved 4X water resistant control panel. This mid-range piece of equipment is undoubtedly a wise choice for small to medium volume production. Alternate capacities and formats are available on request.

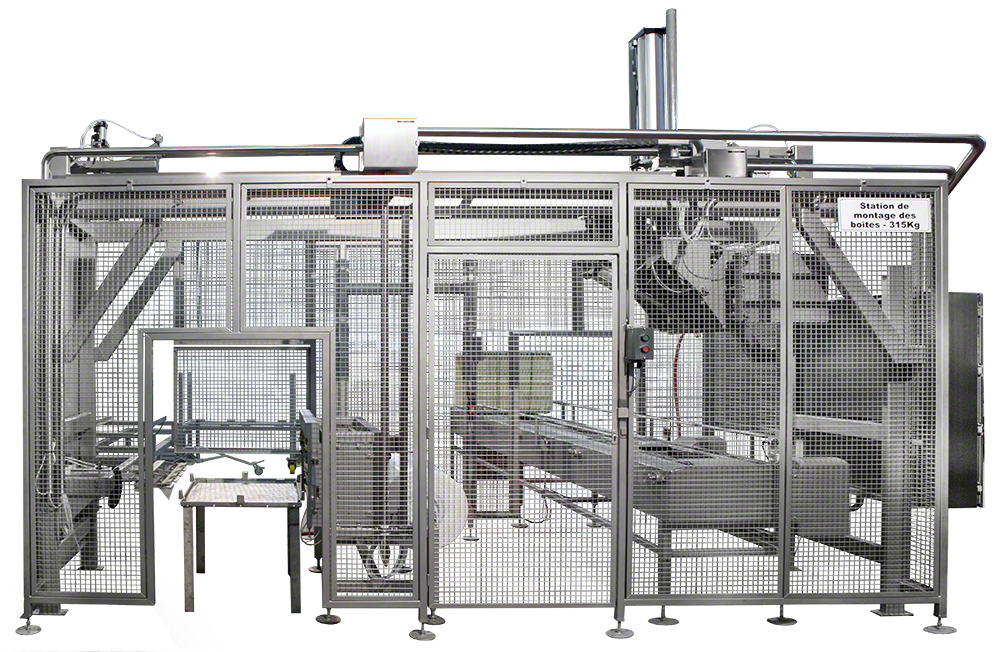

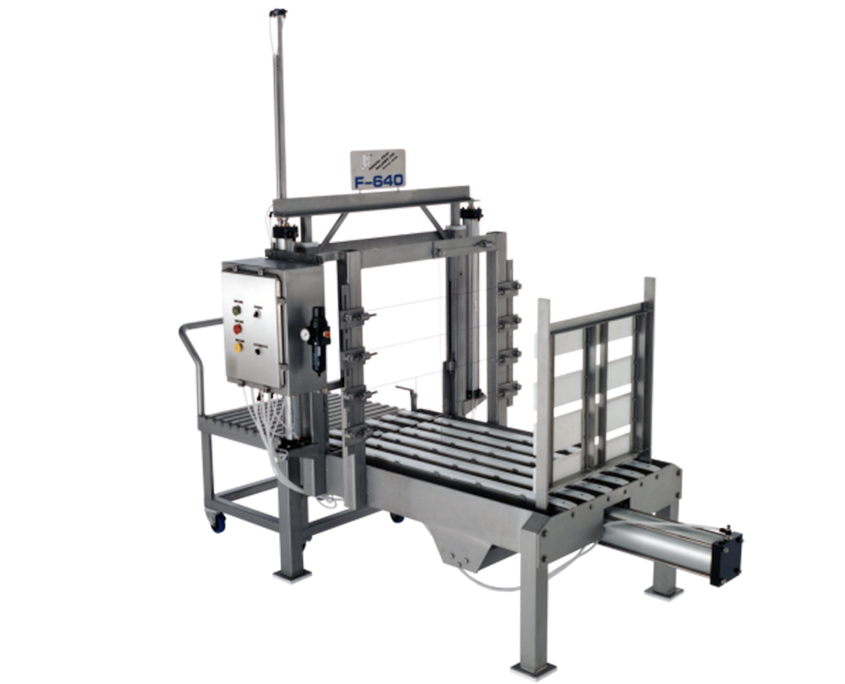

Box-Assembly Station for 640 lb Blocks of Cheese

This sanitary box-assemby station for cheese production is fully automated. It was designed to be integrated into a production line. All electrical components, assembly, programming, and enclosure designs are CSA certified.

40 000 litre Maturation Tanks

These 40.000 litre maturation tanks are designed to process yogurt paste. They are equipped with a large displacement stirring mechanism which ensures a minimal amount of shear in the product so as to maintain its smoothness. With a high heat retention capacity, they provide the required control for the maturation of the product. The installation and connection of the process tanks is accomplished by our specialized teams who will connect the new tanks according to the 3A quality standards and use high quality ASTM-270 pipe fittings.

Processors, Tanks, and Silos

For a number of years now, IAI has been designing and manufacturing a wide range of silos, tanks and processors for the dairy industry, many with 3A and high pressure certifications. Being the fifth largest plant in the world to achieve 3A certification for food process vat manufacturing, IAI has a plant of more than 70,000 square feet and advanced equipment capable of manufacturing processing tanks of up to 15' in diameter and a length of 70' capable of containing more than 350,000 liters of product. No matter what your needs may be, our tanks can be of vertical, horizontal, pressurized or atmospheric design, have a stirring system, a refrigerating or heating wall, be insulated or not, have legs or a skirt, as well as a wide variety of measuring instruments such as pressure, level, and temperature sensors.

2-Stage MC25 Cheese Cutter for 40 lb Blocks of Cheese

Features: Complete unit (available on wheels) with a structure made of 304 stainless steel, aluminum thrust cylinder with stainless steel shaft, and push guides mounted on precision bearings. The unit is equipped with 2 cutting stages adapted to the required dimensions and removable UHMW guide rollers, as well as cutters (harps) with adjustable cutting wires designed for blocks of Cheese weighing 40 lbs. Thrust Cylinder Operation: Hydraulic cylinder operated with FDA vegetable oil, stainless steel oil tank, and compressed air thrust activation. Safety and automation: Screen guards cover cylinders and cutters. The unit is also equipped with detectors that confirm guard closure, a stainless steel control panel for managing the 2 cylinder cutting cycle, including an activation button for the cutting cycle and an emergency stop switch.

Economical Pneumatic Cheese Cutter

In two slicing motions, this multiportion push slicer can cut 40 lbs blocs of into individual portions within a 10-second cycle. Operators must then manually separate portions and feed them into the packaging machine manually. With only one or two operators, this economical machine can deliver up to 60 servings per minute.

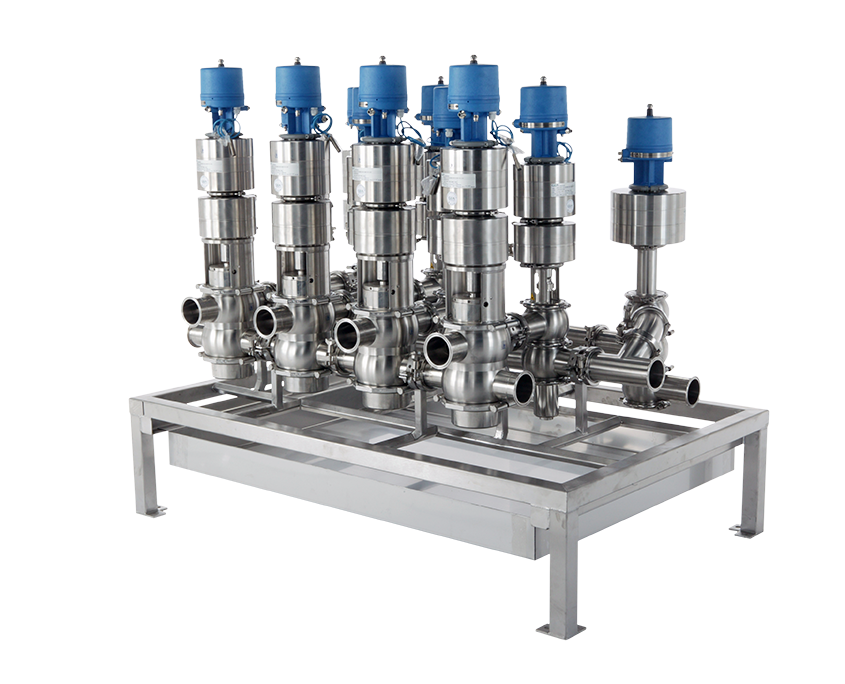

Valve Cluster

IAI manufactures a wide range of sanitary valve matrices for the automated control of liquid products. These matrices allow for flow management without a need for manual connection along with simultaneous circulation of liquids on several levels without risk of cross-contamination. Once the matrix is programmed, it can function autonomously.

Cheese Feeder

Reclinable stainless steel units with control box, dual screw with 3 HP motor, tilting mechanism with safe electric cylinder, swivelling support trolley with control box.

Maxi Process : 9 900 lbs / hour Cheddaring Cheese Conveyor

This cheddaring cheese conveyor in itself alone integrates all the required separation elements of solid/liquid of cheese, including the skimming, draining, mixing and curing. It is designed for a production that can go up to 9.900 pounds of cheese per hour.

Cheese Cutter For 640 lb Blocks to 40 lb Blocks

640 lb block cutting unit Cutting technology with side guide mechanism Minimal adjustment time for the block to ensure a well-centred vertical cut. Precise horizontal cut with ruler. Easily adjustable mechanism with ¼ turn bolts. Design requires very little maintenance.

Cheese Cutter For 640 lb Blocks to 40 lb Blocks

640 lb block cutting unit Cutting technology with side guide mechanism Minimal adjustment time for the block to ensure a well-centred vertical cut. Precise horizontal cut with ruler. Easily adjustable mechanism with ¼ turn bolts. Design requires very little maintenance.