2000 lb Butter Churner

In light of all the knowledge generated by this R & D work on the development and improvement of butter churns, today, IAI is able to offer equipment with a much higher level of reliability and performance. Briefly, our butter churns now enjoy the following features: • Better choice of materials (stainless steel, brass, etc.) to minimize wear and thus increase service life; • Increased reliability of mechanical components, as well as availability of spare parts; • Stronger structure, especially that of the frame. IAI also offers its clients a repair and maintenance service for butter churns in operation. Now, with our new mechanical base, customers can install their existing 1,200-lb, 1,600-lb or 2,000-lb tanks and certain spare parts, such as the engine and gears, can still be used on our base.

5000 lb Butter Churner

Our butter churners are equipped with internal baffles and are available in various sizes and a range of capacities. They have been designed through finite element structural calculations. Our calculation method has allowed us to reduce to the mechanical stress points to a minimum, making it a robust and durable high performance churner. This unit has a capacity of 5000 lb.

Rotary Drum Mixer

Rotary drum mixers are the most economical, effective, and easy to use solution for mixing a wide range of products in many industries. Their primary function is to achieve product homogeneity, which mainly depends on the speed and angle of rotatio. Only products that do not stick or agglomerate can be processed in this type of mixer.

Fruit Mixer

This 500-gallon mixing technology with thermal wall offers the following features: 316 stainless steel basin wall, 35 sq. ft. Of thermal wall for steam circulation at 14 psi, 2 loading doors on hinges, fiberglass wool insulation , Pallet mixer with tefflon scraper, Eurodrive drive unit with speed control, legs with load cell plates, a 3" outlet, and a 200 grit internal sanitary finish.

Vegetable Mixer

This safe and adjustable technology is equipped with two mixing shafts. It is Innovative in design and has fast mixing capabilities. It also includes two shafts with blades for constant mixing and quick emptying after cycle completion. The shafts' bearings are replaceable without any tools - even during production. Two watertight doors can be operated by pneumatic cylinders for draining. This unit includes removable safety guards for the engine, doors, a top opening, an adjustable height, and a 240 grit interior finish.

High Capacity Vacuum Mixer

This complex mixer with fins and ribbons is used by the chemical industry in the production of liquids. It is equipped with 8-meter ribbon mixer (425 operational cubic feet) for dye pigmentation. Furthermore, it has a hydraulic control unit (pump 125HP, torque 270,000lbs. / in.), a central exhaust with a guillotine-style sliding gate, and a hydraulic system for opening the cover.

200 liters pharmaceutical cooker

This mobile unit has a 200 l capacity with internal welds finished at 25 Ra, steam heating at a pressure of 90 psi according to ASME VIII-1 with thermowell, insulation with stainless steel coating, passivation and certification.

200 liters pharmaceutical cooker

This mobile unit has a 200 l capacity with internal welds finished at 25 Ra, steam heating at a pressure of 90 psi according to ASME VIII-1 with thermowell, insulation with stainless steel coating, passivation and certification.

V-Shaped Mixer

IAI can offer you several types of "V" mixers. They are tumbler mixers equipped with two hollow containers forming a V at an angle ranging from 75 to 90 degrees, attached to a rotation axis. This type of unit is the most widely used method of mixing granular substances, especially in the pharmaceutical industry. This easily washable mixer has the advantage of offering high volume and low shear.

Pharmaceutical Buffer Tank

Pharmaceutical Buffer Tank 50-liter mobile buffer tank used for the pharmaceutical industry to supply two filling machines with an operating pressure of 80 psi (FV) according to ASME Code Section V111 div 1 (tank), ASME / BPE 2009 "BioProcessing equipment," and a 20Ra surface finish.

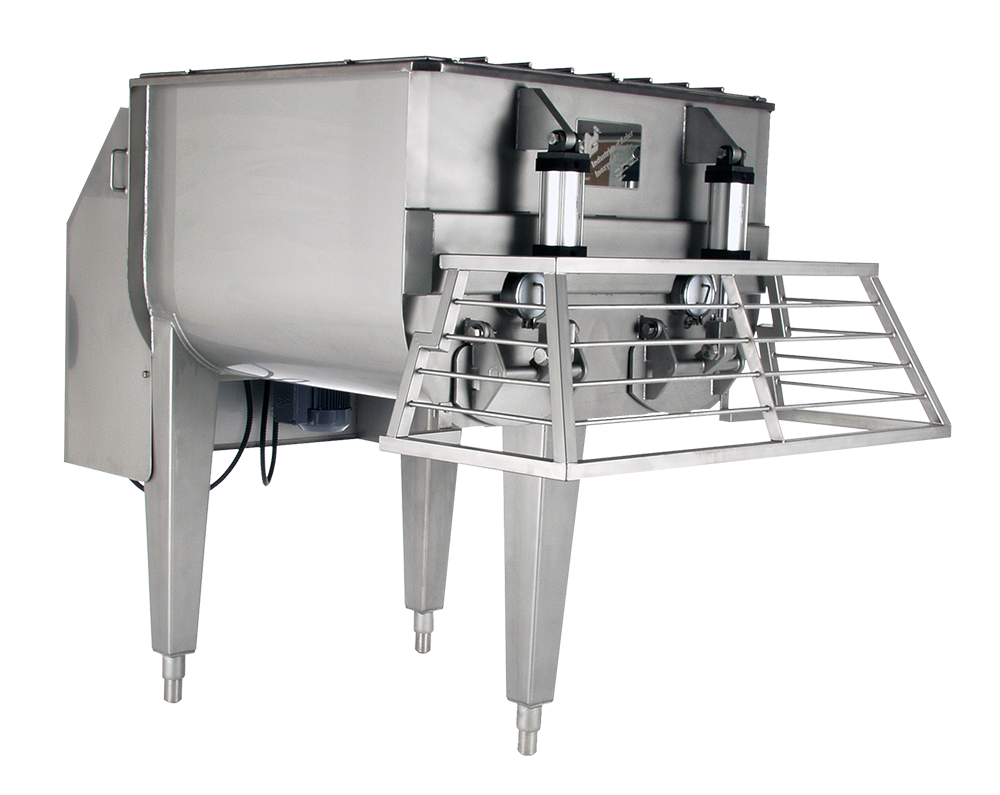

Meat Chopper Mixer

This mobile unit (on wheels) offers a production capacity of 5,500 Kg / hr, reversible rotation capabilities, and a control panel for managing the blending of ingredient. This high-capacity technology is equipped with dual paddle action, a feeder screw powered by hydraulic motor, a 46 cu. ft. Tank., and safety grid.