Automated Powder Dryer

This highly sophisticated drying equipment, designed by IAI for an international company, meets the highest design and manufacturing standards.

Conveyor and Press System for Food Products

This product is an example of a food processing unit with a fully automated continuous conveyor system. This vegetable press removes the maximum quantity of water from a cabbage through a continuous process using a cylinder-operated press, lessening the operators' workload and improving variances due to its constant spinning rate.

Food Dosage Skid

This is a batch preparation unit for food additives. It is equipped with an autonomous hot water tank and allows for recipe selection with the help of an operator interface, the manual addition of ingredients, and mixing by recirculation. The hot water tank has: a 245 litre capacity; an insulated heating element; a cover with sanitary finish; 24 "x 32" of ferrule; 2 safety valves; as well as a flanged and dished head and bottom. Its operating pressure is of 100 psi. It is also equipped with a single-walled 340 litre preparation tank with a sanitary finish. This tank has a conical top and bottom, 30''ø x 28 '' of ferrule, atmospheric pressure operation, a circulation pump, an agitation system, as well as a control box with an operator interface for batch preparation, mixing, and transfer to production.

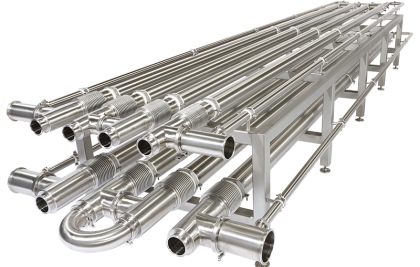

Ring Cooler and Exchanger with Four Concentric Tubes

In this annular exchanger, the product circulates in a ring between two fluids in order to heat or cool it as required. Furthermore, it is equipped with a large exchange surface for fast heating or cooling and is suitable for viscous products with low pressure drop. Passage distance ranges is from 4.5 to 17.5mm. They are available in lengths of 10 and 20 feet with diameters ranging from 1 to 6 inches.

Fluidized Bed

High-throughput drying by displacement of dehydrated blueberries received from a continuous macerator. Risks of degradation and agglomeration of small fruits are minimized during displacement thanks to a drying tunnel equipped with a vibrating conveyor under a fluidized bed which is divided into separate sections. Each section is equipped with different temperature and air flow control.